How a Well is Built

This life changing development is possible when a water well is installed in their village. Wells equipped with hand pumps are among the simplest of community water supply technologies. Compared with electric or diesel pumps, hand pumps require substantially less financial resources, are far easier to maintain and less likely to break down. Hand pumps use human power and the mechanical advantage of a lever to lift water up from a borehole drilled deep into the ground.

In South Sudan, there is a bountiful supply of water deep beneath the ground – the issue is accessing it. That’s where we come in!

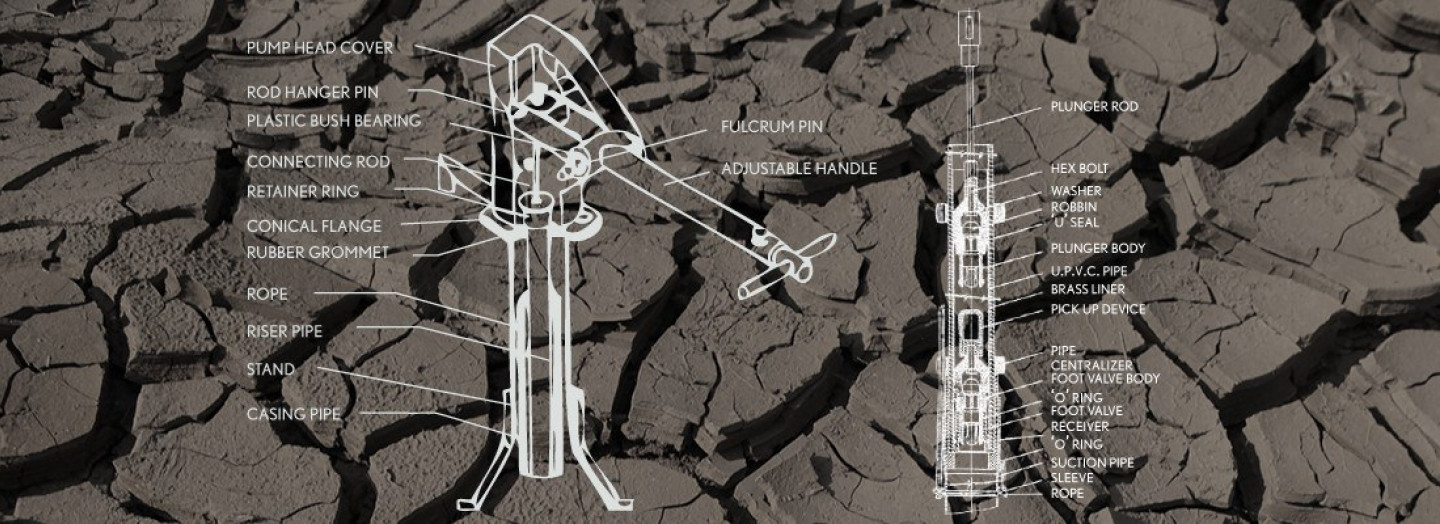

We use the India Mark 2 pump system, which is the largest selling hand pump in the world and is the backbone of community water supplies in villages across Africa. This pump is designed for heavy-duty use in communities of 300 persons or more and for depths of up to 80 meters.

Installing a borehole equipped with a hand pump is a 6-stage process.

1. SITE SELECTION

Selecting the site of the borehole carefully minimizes the risk of a dry or low yielding well and ensures the needs of the community are met. At this time a community water committee is formed. These five people, at least two of which should be women, are expected to ensure that the area around the well is fenced, kept clean, collect user fees and oversee any necessary repairs. We want communities to be self-sustainable, so forming a committee is an integral step toward communal development and growth.

2. MOBILIZATION AND SITE PREPARATION

This refers to getting the needed equipment and personnel to the job site. The distance from base, the road conditions, the availability of materials and gas and the security situation can all have a big impact on how quickly work can begin. Concurrently the community is preparing the site by clearing brush, trees and other impediments.

3. DRILLING

The drilling process can take up to three days depending on the geology of the ground and the equipment being used. If a rock is hit air drills may become necessary. During drilling surface casing is often required to prevent the borehole from caving in.

4. CASING AND COMPLETION

Once drilling has been completed the well screen and casing needs to be installed and the gravel pack, grout sanitary seal and backfill placed. Small diameter gravel filters debris out of the water before it seeps into the perforated casing and is then pumped to the surface.

5. WELL DEVELOPMENT & PUMPING TEST

Once construction is completed the water well needs to be cleaned and developed. Cleaning involves flushing the well with chlorinated water for 4-6 hours to ensure that any contaminants introduced during the drilling process are removed. A submersible pump is lowered into the borehole to flush the system of contaminated water. Following this a pumping test and water sampling is required to verify the flow rate and water quality.

6. PLATFORM CASTING & PUMP INSTALLATION

The wellhead is set into a cement platform, which is left to cure for 1 day. A 6-meter runoff trough is also cast in cement to prevent water from pooling around the wellhead and seeping back into the borehole and contaminating it. Once the platform has cured the final components of the hand pump are installed. The well is now ready to be used.

Support projects like this. Donate today.